Guangdong Xianjing Polishing: Innovator of Vibratory Polishing Machine Technology, Defining New Benchmarks in Precision Machining

Focus on Ultimate Efficiency, Empowering the Future of Intelligent Manufacturing

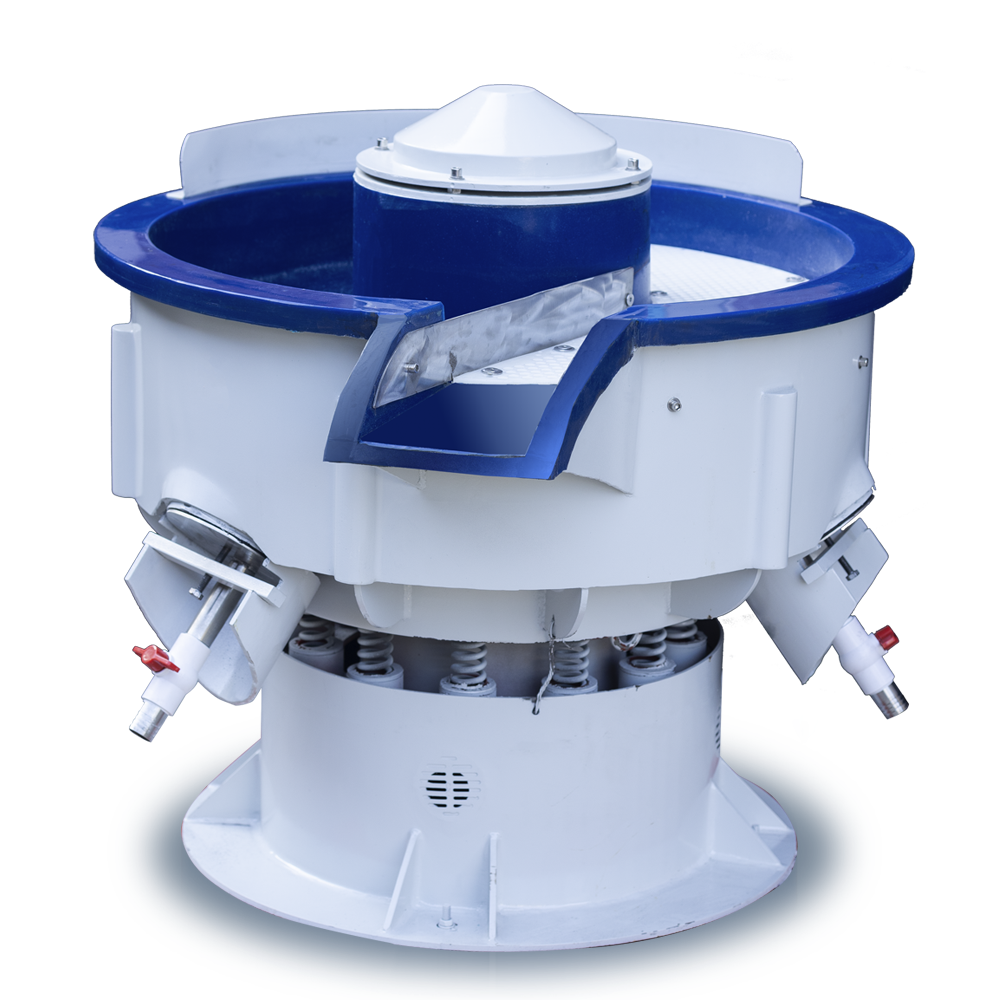

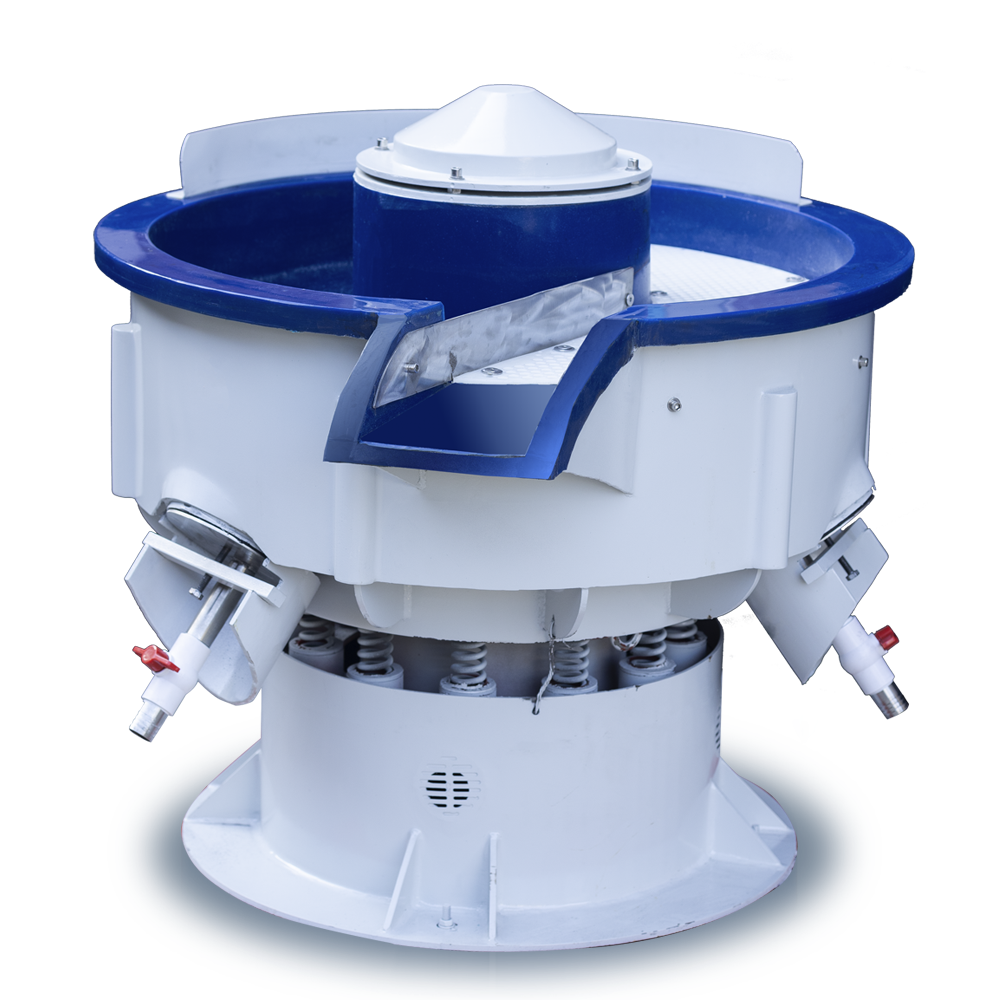

Guangdong Xianjing Polishing Industrial Technology Co., Ltd. takes innovation as its engine and integrates global cutting-edge vibratory polishing technology to launch a new generation of high-efficiency intelligent vibratory polishing machines. Specifically designed to provide nano-level precision machining solutions for fields such as aerospace, new energy battery materials, 3C electronic ceramics, and medical implant devices, it breaks through traditional polishing bottlenecks to achieve highly uniform and low-damage processing of complex workpieces. The surface roughness can reach Ra0.01μm, with both precision and efficiency advancing in parallel.

Variable Trajectory Vibration Technology: Adopts an eruption-like composite vibration trajectory combining linear, circular, and elliptical motions, improving polishing efficiency by 50%. It effectively eliminates the low-energy zones of traditional equipment, and large-capacity grinding cylinders (diameter > 650mm) still maintain an ultra-high energy efficiency ratio.

Intelligent Temperature Control and Load Sensing: Equipped with built-in temperature sensors and real-time load monitoring, it supports cryogenic polishing (-40℃) and switching between dry and wet grinding. This avoids denaturation of heat-sensitive materials and ensures sample activity.

Digital Precision Regulation: The touchscreen integrates segmented settings for rotation speed, time, and interval cycles. The parameter storage function ensures process repeatability, with a uniformity error of ≤±0.1μm.

Multi-Material Adaptability: Offers 7 types of polishing kits (zirconia, stainless steel, polymer composite materials, etc.), compatible with hard and brittle materials (silicon carbide, sapphire) and paste-like viscous samples, achieving a cell wall-breaking rate of >95%.

Energy consumption is reduced by 40%. The sealed dust-proof design combined with an abrasive recycling system reduces waste emissions by 60%, complying with the ISO 14001 environmental standards.

Full-Chain Technical Closed Loop: From equipment research and development, abrasive formulation (patented composite abrasives) to process optimization, providing turnkey projects.

Global Cutting-Edge Certifications: Passed CE and SGS certifications, with core components made of aerospace-grade materials, extending service life by 50%.

Zero-Distance Response: Customized solutions within 48 hours by the engineer team, with lifelong technical maintenance, covering over 30 service outlets nationwide.

Making precision visible, making intelligent manufacturing predictable. Guangdong Xianjing Polishing reshapes the new era of vibratory polishing with the genes of "China Intelligent Manufacturing".