During the grinding process, the type and particle size of abrasive should be selected based on the shape and characteristics of the workpiece. The shape of the workpiece is generally a circular arc, with a fillet radius of 0.8 mm or more. In order to improve processing efficiency, methods such as coarse grinding, ultrafine grinding, or ultrafine machining are often used.

Generally, abrasive is used for rough surface grinding of workpieces, and various methods such as grinding (including precision grinding) and chemical polishing (including electrochemical polishing) can also be used to complete the grinding process. After grinding, the product will produce fine sand particles on the surface, and the wear amount varies with the grinding depth and process method. Mechanical grinding is mainly a processing method that uses mechanical tools to polish workpieces to achieve surface smoothness requirements (usually also known as mechanical ultrafine grinding).

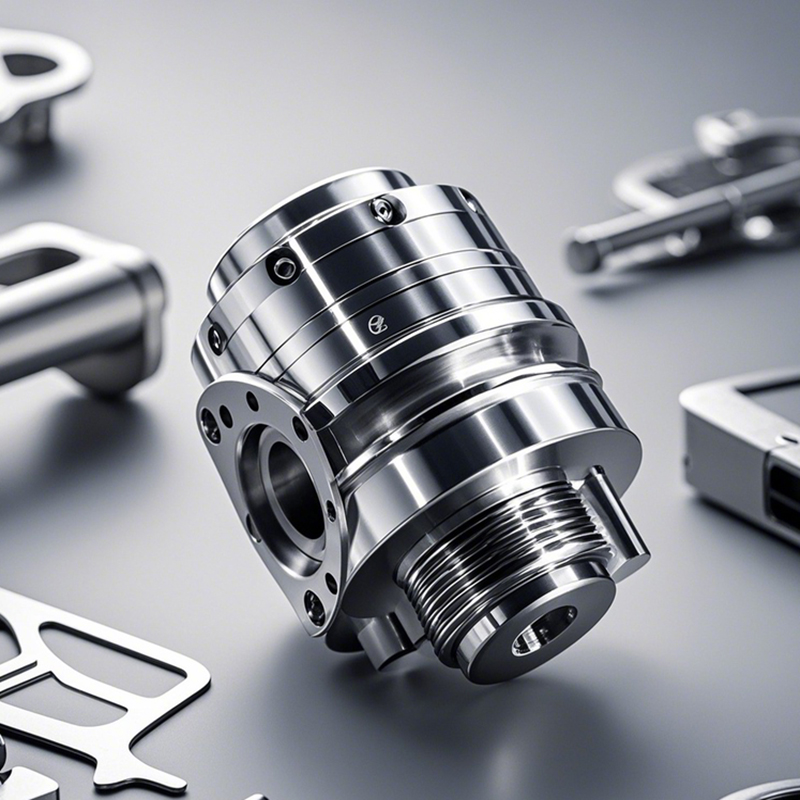

Many automotive components require abrasive machines to meet demand.

If you need Abrasive Machines, Polishing Compounds, and consumables, please feel free to call us for consultation!